Welcome to this HP Site Flow whitepaper on print workflow automation. This is part of a series of whitepapers commissioned by HP in 2020 and provide a thorough independent analysis of current workflow trends and the benefits that it can bring across verticals. From capturing digital labels and packaging through short-runs and mass customisation to scaling to thousands of orders without falling apart, this series is designed to help any print service provider get the full picture. The whitepapers can be read in full on this site or downloaded instantly as a PDF with no pesky forms to fill out. From all of us in the HP Site Flow team, we hope you find the series useful.

Keypoint Intelligence White Paper: Quicker customer and job onboarding to faster revenue

Introduction

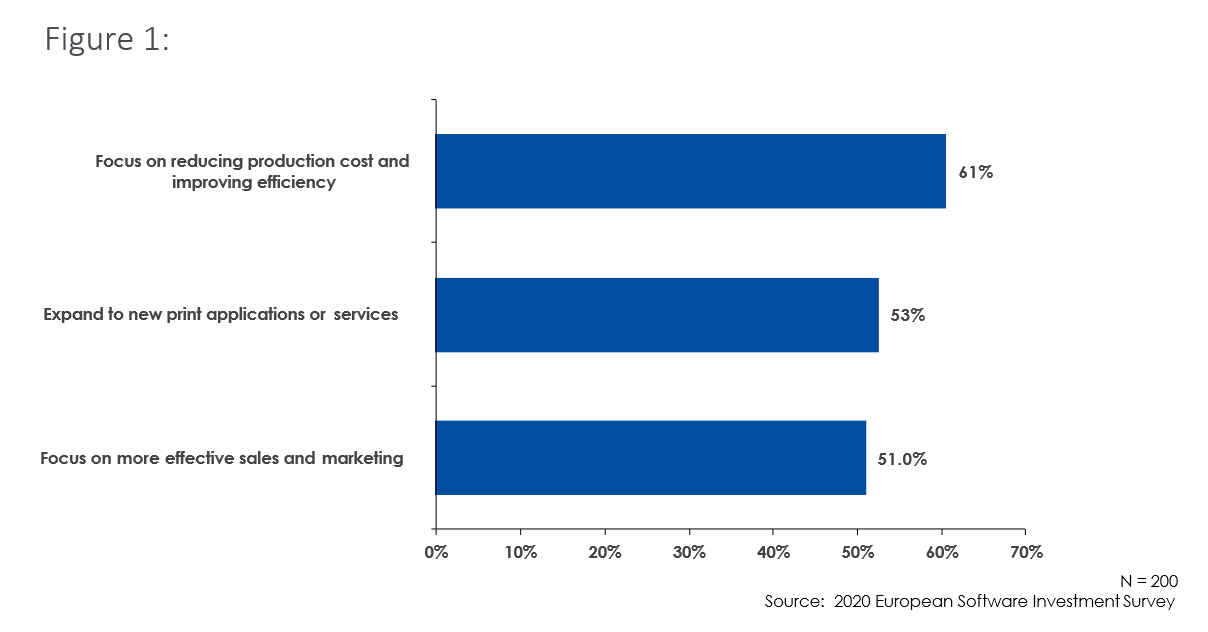

Most printers are focused on improving operational efficiencies, expanding applications offered to customers, and focusing on more effective sales and marketing to grow their businesses. Adding new customers and orders to the sales funnel, while servicing existing customers at a high level, is critical for sustained growth. The challenge is getting the customer setup so orders can be placed, and jobs moved efficiently into an end-to-end print production workflow.

Top Strategic Initiatives of PSPs

Onboarding new customers can take anywhere from days to months depending upon the client’s requirements, type of applications being produced, method for placing orders, technical setup and integrations, along with the level of customer engagement expected. The best customers are long-term ones that have repeatable, programmatic print needs— but these typically need additional time to onboard. The time it takes to onboard a new customer varies due to:

-

The customer’s specific turnaround times, which may be specified with a contractual service level agreement (SLA). These can be simple with a standard time obligation for all orders, such as 24-hour turnaround, or can be more complex based upon the type of product or business lines.

-

Production workflows and requirements vary based on the number and complexity of the products being produced. For example, a book has different processing and production steps compared to business cards.

-

Job submission also changes the time required to onboard a customer. A customer looking to integrate their procurement system with the printer’s management solution requires technical integration and testing, whereas a customer submitting orders through online file transfer or FTP are faster to initially setup.

-

Customers that would like to implement user management, approvals, and status notifications also take more onboarding time.

Customers are Unique, but their Onboarding Shouldn’t Be

Every customer and the industries they serve have a unique set of print needs and requirements. The printed products (e.g., a folded brochure) may be the same, but turnaround times and quality expectations often vary. Since the applications are technically similar, the customer onboarding should not be unique but instead follow a standard production procedure that can quickly be deployed.

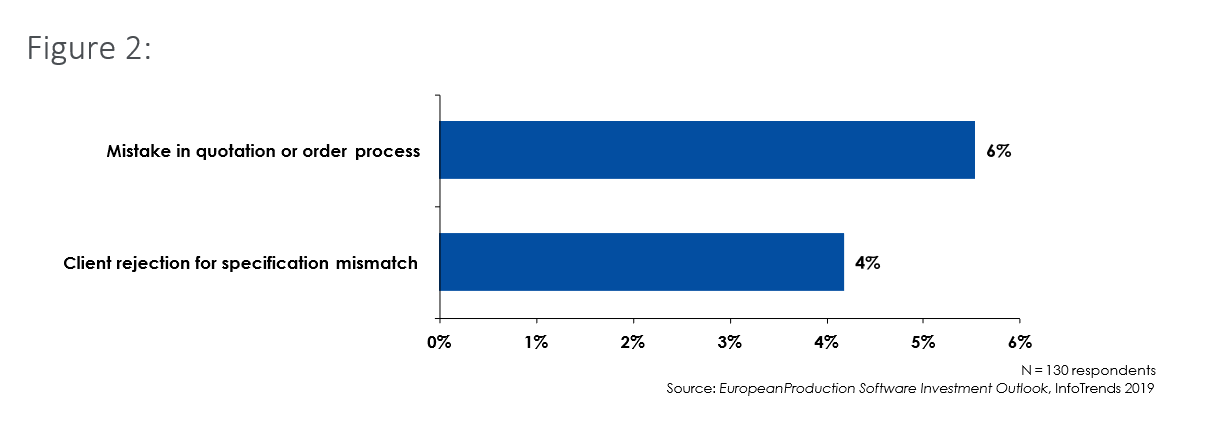

€3.5M Amount of waste possible for the average European printer from mistakes in quoting and client rejection for a specification mismatch

Having a flexible, end-to-end workflow platform is critical for today’s print operations. When each client has customized business rules, a structured production path can be followed. The faster new customers can be onboarded, the faster orders can be submitted and revenue collected.

The customer onboarding process establishes how the customer will submit orders along with the artwork and possible data files. The customer will also specify SLAs, approval methods, and notification preferences. Building structure and defined workflow paths not only speeds up customer onboarding, but can minimise costly errors that lead to waste.

How much money can your print operation save by optimising customer and job onboarding?

According to research by Keypoint Intelligence, the average European printer discards 6% of work due to mistakes in the order process and 4% due to rejection by the client based on a specification mismatch where the final product does not match the client’s initial request. While these percentages may seem insignificant, the impact can be up to €3.5 million(1) per year.

Common Errors that Lead to Waste

HP Site Flow, an end-to-end print workflow automation solution for workflow and production management that can minimise production errors in several ways. By adapting to the customer’s preferred method for submitting jobs and capturing critical production details using a structured method, HP Site Flow reduces the possibility of human errors in data entry that can lead to rejected work due to mismatches (e.g., using the wrong paper type). Furthermore, HP Site Flow consolidates client orders from many sources into one end-to-end workflow to optimise production through preflighting, batching, and SLA management.

Jobs from Everywhere to One Workflow

HP Site Flow streamlines the process of receiving customers’ artwork and job files, enabling further workflow automation. In days past, job onboarding was simpler. A customer simply brought the necessary files to the print shop on a disc or other physical media. Today, there are many paths for customers to submit job specifications and artwork. Unfortunately for many printers, the most used method is through e-mail. While e-mail is convenient, it lacks structure and has file size limitations to attach artwork. The result is that critical order and production information—such as quantities, due dates, and materials—may not be provided in e-mail by the client. The omission of key information causes back-and-forth communication between print shop staff and the client, greatly increasing the risk for errors.

€17.5K Potential labour cost saving from automating file retrieval for incoming print orders.

Printers that use e-mail, FTP, or online file transfer solutions also incur another cost: the cost of time. Keypoint Intelligence found that file retrieval averaged nearly 17 minutes.

Considering that printers retrieved and processed, on average, between 1,800 and 60,000 jobs annually, the labour costs quickly compound. By automating file retrieval, Keypoint Intelligence estimates printers could save at least €17.5K in annual labour costs. There are clearly better methods for job onboarding! HP Site Flow can onboard jobs through integrations with web-to-print solutions, other software using application programming interface (API) capabilities, HP Piazza, HP Brand Centre, various SDKs for leading platforms, and through bespoke integrations (if needed). For clients that may not be ready for that level of automation, the print shop’s customer support representatives can place orders for the customer through a simple web browser interface. This ensures the customer’s intent is adequately captured and files can be supplied without the fuss of being rejected through e-mail.

HP Site Flow is the Customer Enabler and Automator

HP Site Flow addresses one of the biggest workflow challenges of today’s printers: onboarding client’s and their jobs. Enabling automation makes printers more efficient, but also enhances the customer experience and satisfaction. Customers can submit orders in a way that works for their business and employees, knowing that their print jobs are processed according to their unique business requirements.

Printers can increase their speed-to-market by automating important workflow functions with one solution (HP Site Flow) that offers customizable end-to-end workflow functionality, instead of needing to integrate multiple software solutions. Many printers (41%) have mostly manual workflow processes in more than one department with pockets of automation for certain tasks. Unfortunately, most printers have yet to automate end-to- end print production tasks that have a huge impact on the labour hours required, the cost of materials, and the waste associated with errors in their print operations. For example, 96% of printers have yet to automate shipping, 94% continue to create impositions manually, and 64% do not take advantage of combining similar jobs through batching.

PSPs that do not invest in end-to-end automation not only lose a competitive edge, but also the savings in hard costs.

Once customers and jobs are onboarded to HP Site Flow, the system automatically starts processing those orders based on business rules and workflow plans to meet that customer’s specific requirements. The files are preflighted to check and fix common issues before production, such as missing fonts or low-resolution images. Jobs are then queued and batched together based on criteria, such as due dates or type of work. Orders are then combined into batches to minimise the amount of material and cost, considering current production constraints and available equipment. Jobs are tracked using barcodes through all production steps, staged, and packed to save shipping costs. Time and cost savings are accumulated end-to-end along each process compared to traditional workflow methods.

HP Site Flow is a single, end-to-end workflow platform to fast track your print workflow automation so you can be more efficient than most of your competitors and, just as importantly, exceed your customer’s expectations.

- Value based on an average of 10,500 jobs produced per year at an average order value of €3,441.